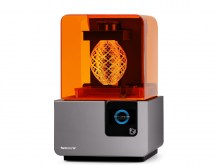

Stereolithography (SLA) 3D printing uses a laser to cure solid isotropic parts from a liquid photopolymer resin. This allows the user to 3D print strong, detailed models with stunning surface finishes. This 3D printer has a maximum build volume of 14.5 × 14.5 × 17.5 cm (5.7 × 5.7 × 6.9 in) and an axis resolution (layer thickness) between 25 – 300 microns (.001 – .012 in). The Formlabs Form 2 printer has set industry standards for SLA 3D printing, which is why it is used by companies such as Boeing, Tesla, Google, and Ford. This 3D printer is used to support undergraduate Capstone projects, graduate research projects, and postdoctoral research on campus where strong models with smooth finishes are required.